9

9

1. Adapt to different types of processing of many material systems

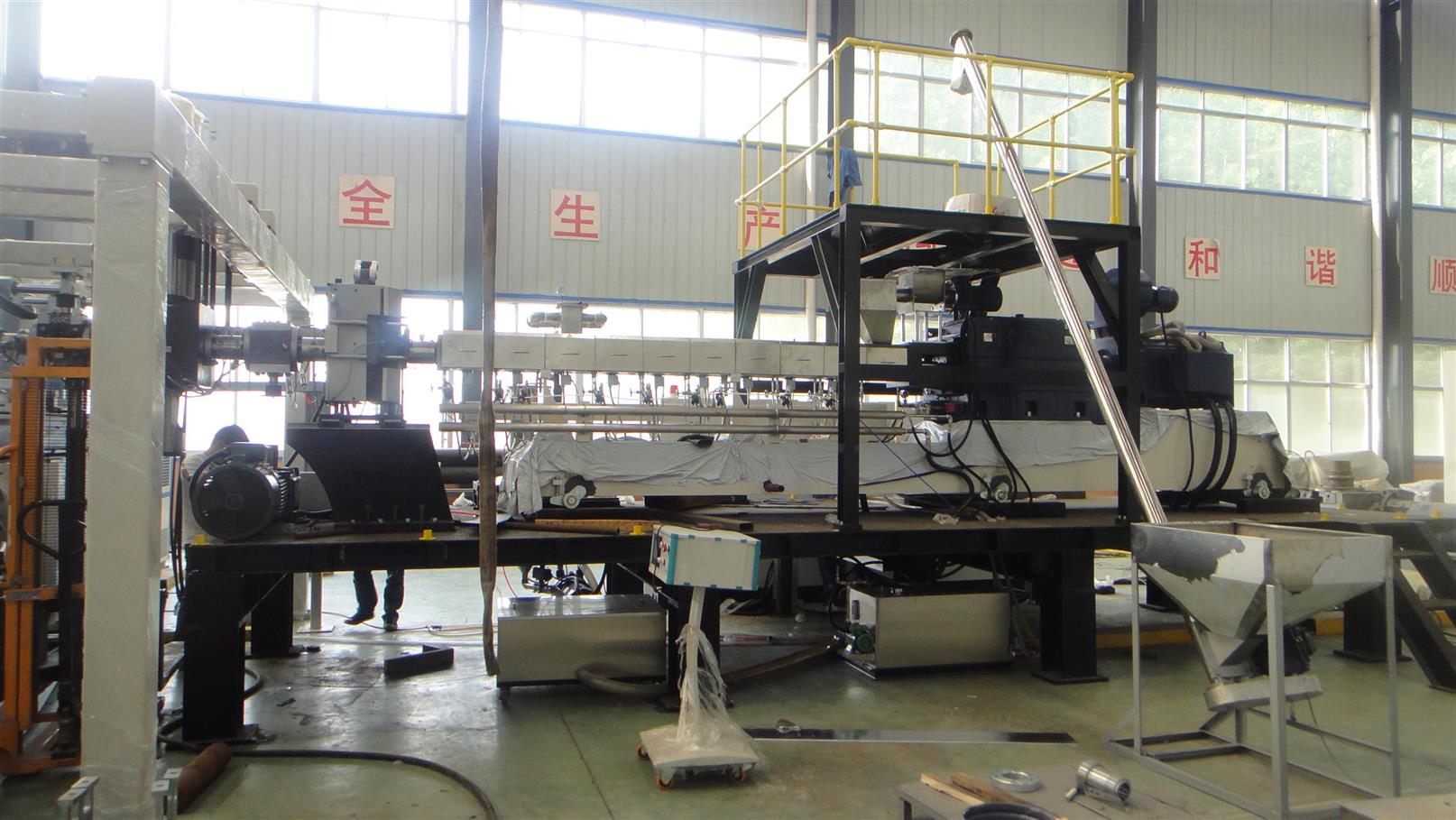

2, from loading to rewinding, a full set of integration, can do turnkey projects

3. Large output, low energy consumption and high degree of automation.

At present, there are two main methods for the production of PVB interlayer film, one is the over-roll method and the other is the water-pass method. The over-roll method is to produce a film by casting two rolls or three rolls (with a light roll and a pattern roll). The over-roll method has low investment, the technology is relatively mature, and the equipment is relatively easy to operate. The water-passing method is a process that is generally believed to produce a film with better whiteness and a more uniform pattern. It uses a water tank to cool the characterization instead of a roller, and then removes water, thickness, oven, cooling, separator composite, and traction. Finally, the volume is collected. Because the over-water method has more advantages than the over-roll method, it is used by more and more manufacturers. The following points in the production process of the water-passing method require special attention:

因为过水法产品优点多于过辊法,被越来越多的厂家所采用。过水法生产过程中有以下几点需要特别注意:

水箱的设计。水箱的大小、数量也与生产线的速度产量有直接关系,保证水箱的温度均匀、水循环不引起波动,这是重中之重。

he oven is heated and cooled. In order to increase production and ensure high-speed production of the production line, our company has unique insights and designs in the oven, heating and cooling sections. The oven plays the role of removing the excess moisture of the film, and more importantly, it removes the internal stress. The internal stress in the film can be completely removed, which can effectively prevent the film from shrinking during the high temperature bonding with the glass. The amount of control is better.