10

10

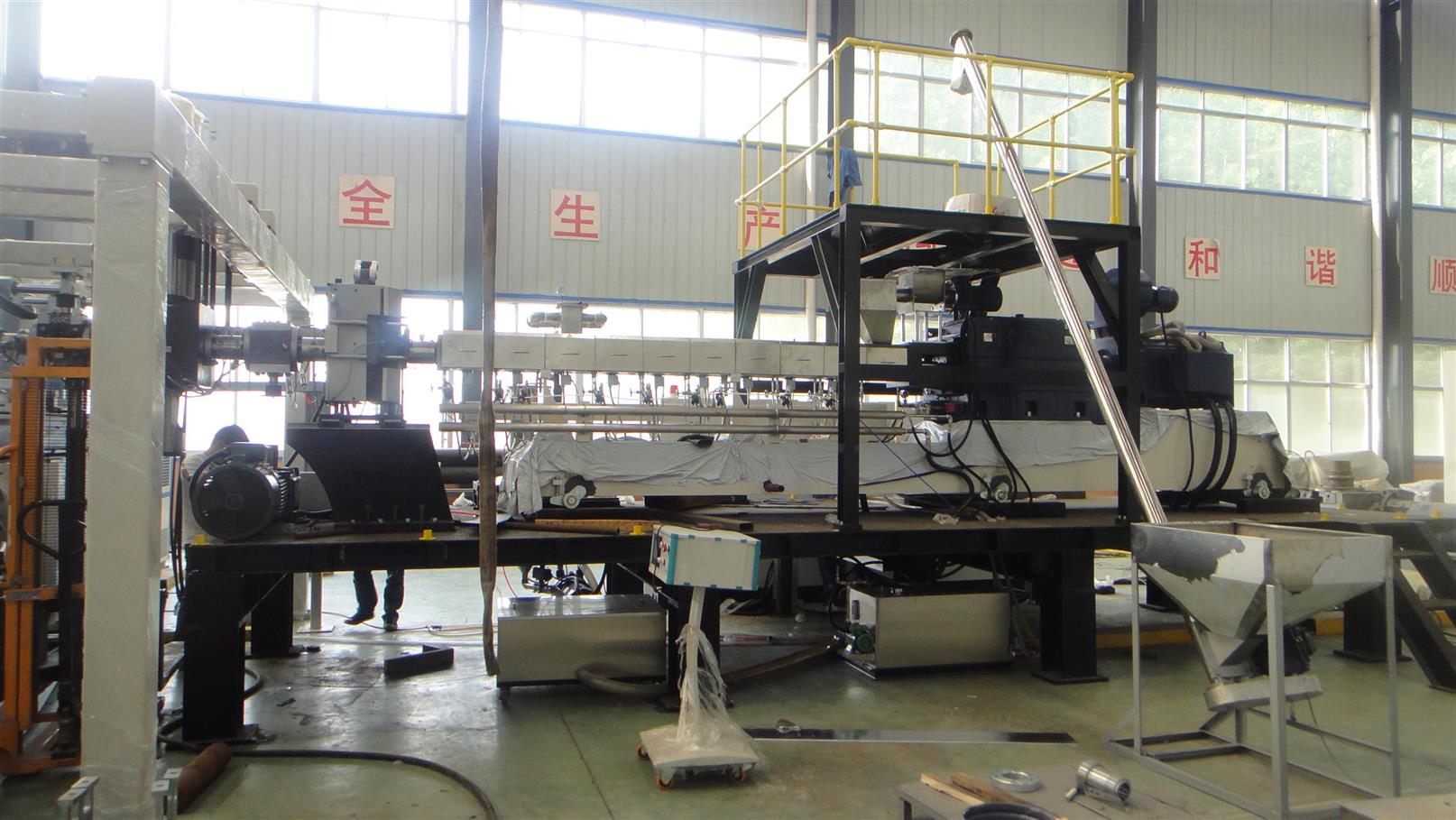

目前,PVB中间膜的生产工艺主要有两种方式,一种是过辊法,一种是过水法。过辊法是采用两只辊或三只辊(有光辊,有花纹辊)流延的方式生产出胶片。过辊法投资低,技术相对成熟,设备也相对容易操作。过水法是普遍认为生产的胶片白度更好、花纹更均匀的一种工艺,它是采用水箱冷却定性而非辊筒,然后经过除水,测厚,烘箱,冷却,隔离膜复合、牵引,后收卷。因为过水法产品优点多于过辊法,被越来越多的厂家所采用。

风量、风刀的造型和设计。过多水分如果长时间滞留,对胶片质量也会产生影响,现在普遍采用刀,风刀数量已足够,关键在于风刀的设计、选择和位置。

PVB玻璃夹层膜厚度一般为0.38mm和0.76mm两种,建筑级pvb中间膜机组,对无机玻璃具有良好的粘结性,具有透明、耐热、耐寒、耐湿,机械强度高等特性。 PVB薄膜主要用于夹层玻璃,是在两块玻璃之间夹进一层以聚乙烯醇缩丁醛为主要成分的PVB薄膜。

he oven is heated and cooled. In order to increase production and ensure high-speed production of the production line, our company has unique insights and designs in the oven, heating and cooling sections. The oven plays the role of removing the excess moisture of the film, and more importantly, it removes the internal stress. The internal stress in the film can be completely removed, which can effectively prevent the film from shrinking during the high temperature bonding with the glass. The amount of control is better.