10

10

he oven is heated and cooled. In order to increase production and ensure high-speed production of the production line, our company has unique insights and designs in the oven, heating and cooling sections. The oven plays the role of removing the excess moisture of the film, and more importantly, it removes the internal stress. The internal stress in the film can be completely removed, which can effectively prevent the film from shrinking during the high temperature bonding with the glass. The amount of control is better.

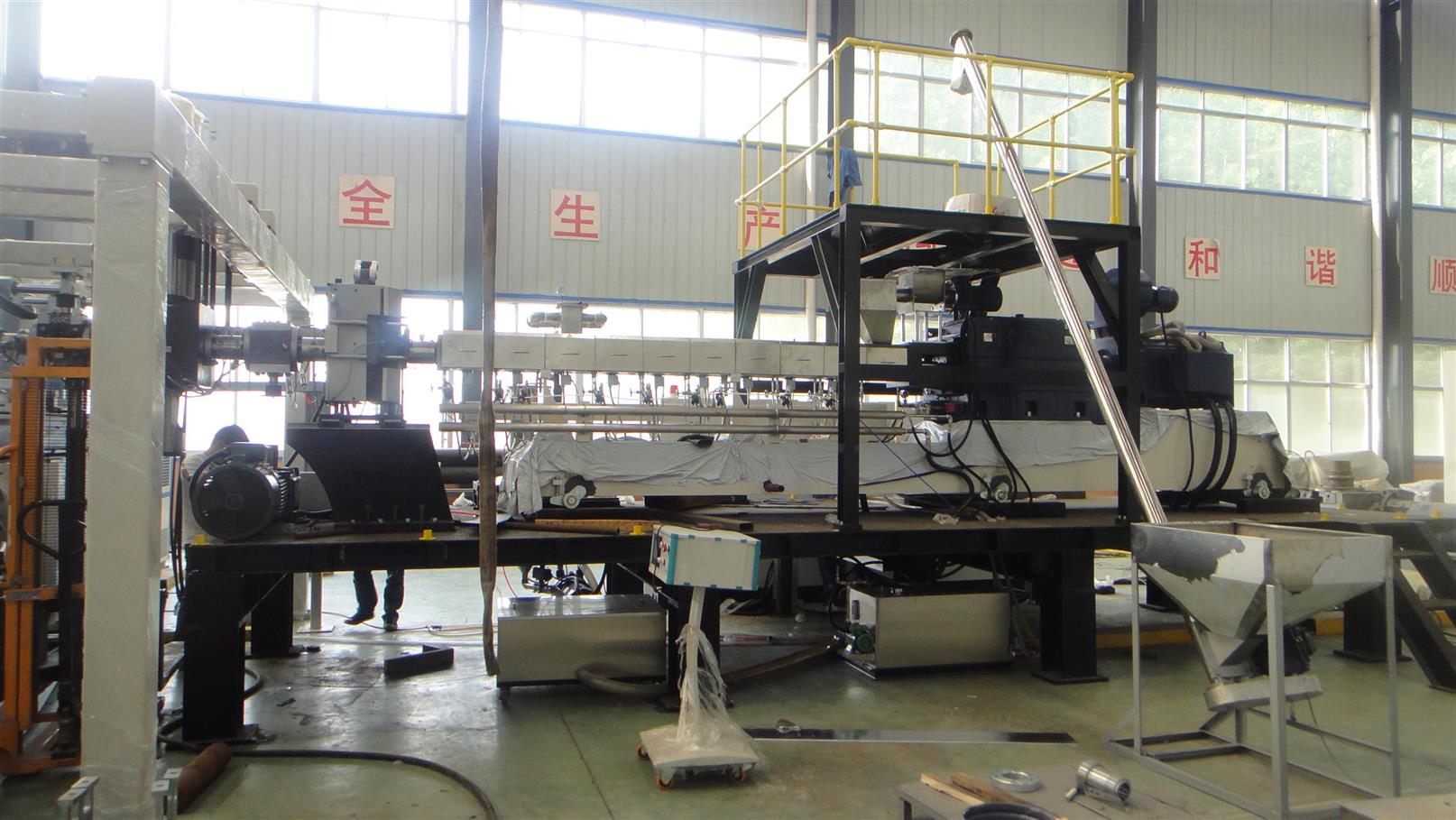

PVB glass interlayer film production line is our company's latest design concept, with reference to the production characteristics of pvb interlayer film, designed and produced professional equipment. Since 2012, the company has produced 2800mm, 3550mm, 4200mm and other PVB intermediate film production lines with a maximum output of 800kg/H and a thickness of 0.38-1.5mm. The production line has the following characteristics:

PVB胶片现市场上主要以原色胶片(用于建筑类夹层玻璃)和彩条胶片(其中彩条胶片又以蓝带和绿带为主,用于汽车前风挡玻璃).(也有其它颜色胶片.) PVB(原色胶片)外观为半透明薄膜,无杂质,表面平整,有一定的粗糙度和良好的柔软性,对无机玻璃有很好的粘结力、具有透明、耐热、耐寒、耐湿、机械强度高等特性,是当前世界上制造夹层、安全玻璃用的粘合材料,同时在建筑幕墙、招罩棚、橱窗、银行柜台、监狱探视窗、炼钢炉屏幕及各种玻璃等建筑领域也有广泛的应用

电气控制。做为一种高端应用产品,胶片的各个指标要求都很高,只有高度智能的自动化控制才能满足高品质产品的要求。其中挤出机的压力自调,收卷的张力控制更是重要。